Enclosures

Pillen Group uses sheet metal processing to make high-quality casings for various markets, including the flow meter industry.

More information?

Description

Series sizes and production

The enclosures are produced and delivered in recurring series of 50 pieces.

Materials

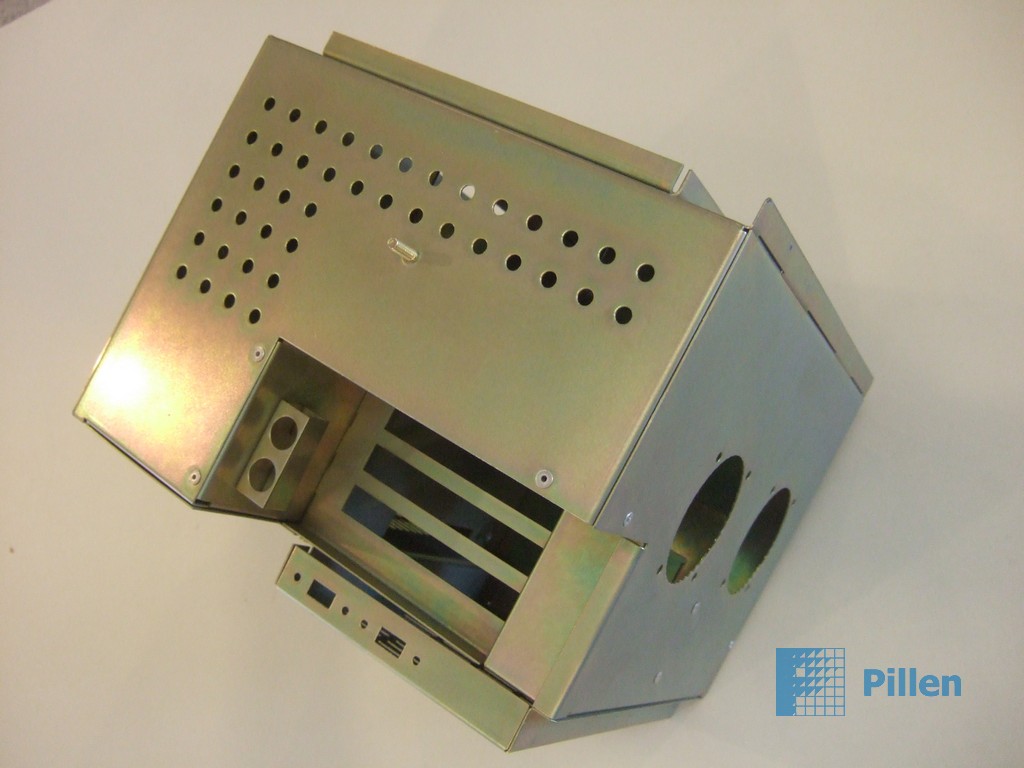

The materials used consist of different materials such as Zincor, steel, aluminum and stainless steel. In the example below you see a stainless steel housing (plate, pins and press nuts).

Production

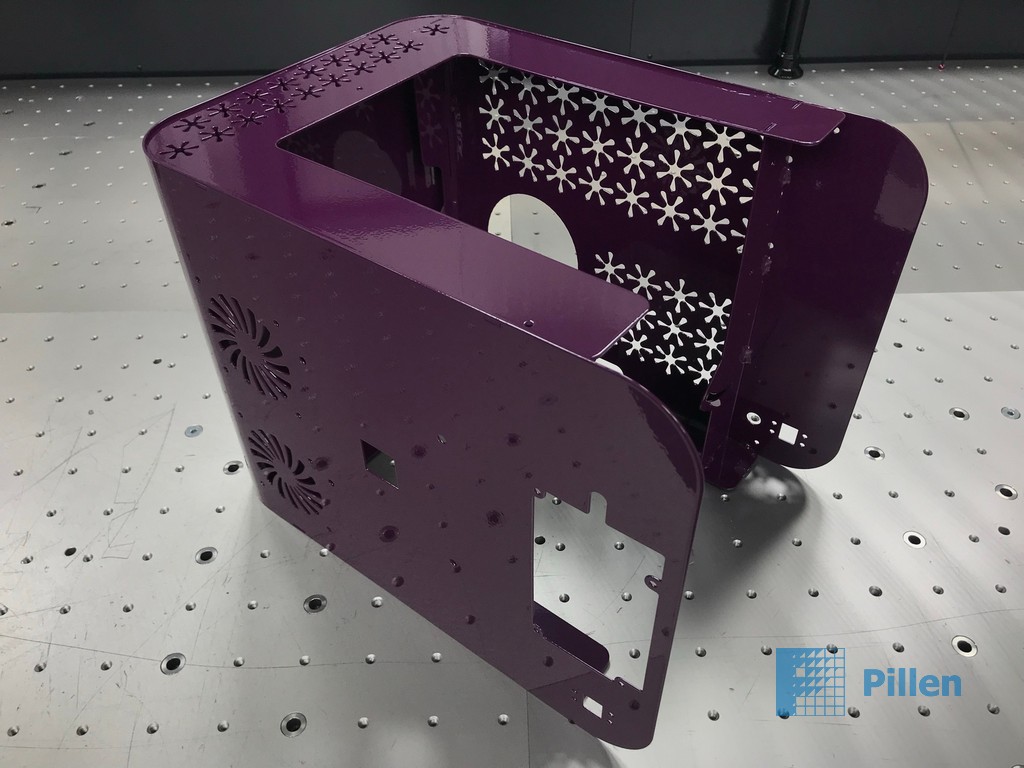

Below are examples of high-quality and accurate housings for a device that is made of stainless steel sheet metal, which involves various processes such as: fiber laser cutting, bending, pressing and welding.

It is important in this entire process that the dimensions are very accurate and must be closely monitored in various areas, since bending and welding can cause the dimensions to deviate quickly (tensions in the plate). The visual aspect in terms of finishing must also be done accurately and carefully.

Photos & images

Other services

Research & engineering

The production method and approach in terms of engineering and automation is important to guarantee constant quality.

Post-processing

The casings are taped and carefully provided with a high-quality powder coating. Visually, the casing must look good and also meet certain powder requirements and visual inspections.

Measurement and control technology

The products are randomly checked at crucial points using our measuring techniques to ensure the stable process.

Where can you find these enclosures?

These enclosures are used in equipment, flowmeter machines and analytical equipment.