Body covers

At Pillen Group we process different types of body covers (also called housings) from different alloys (raw materials) for various purposes.

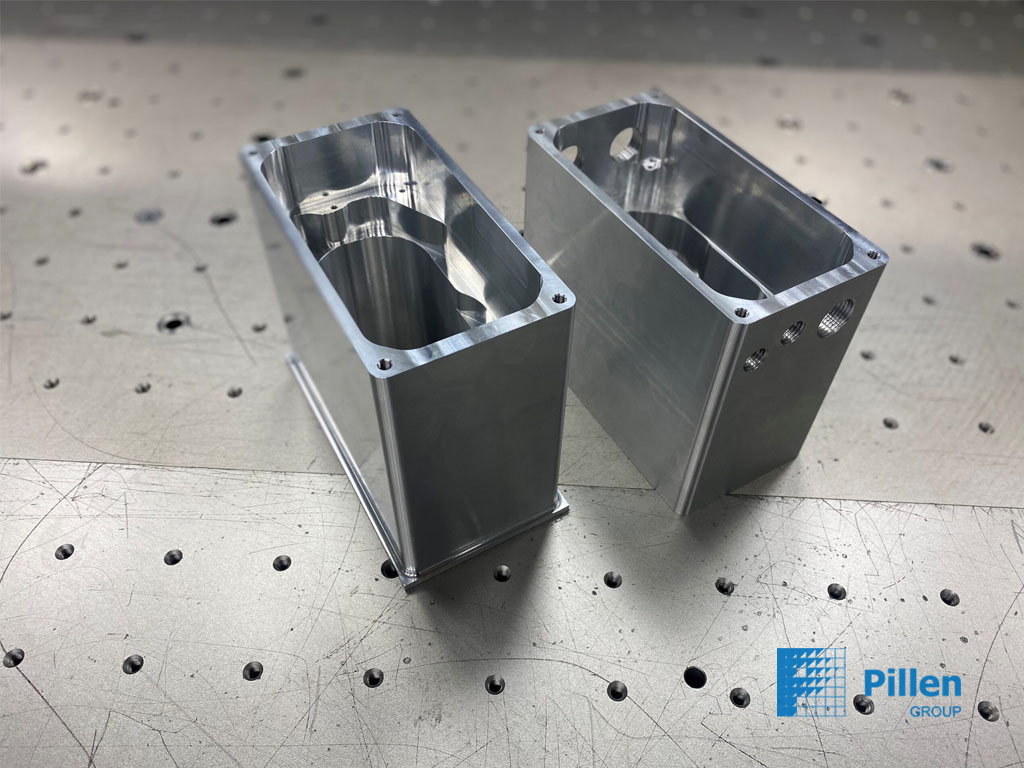

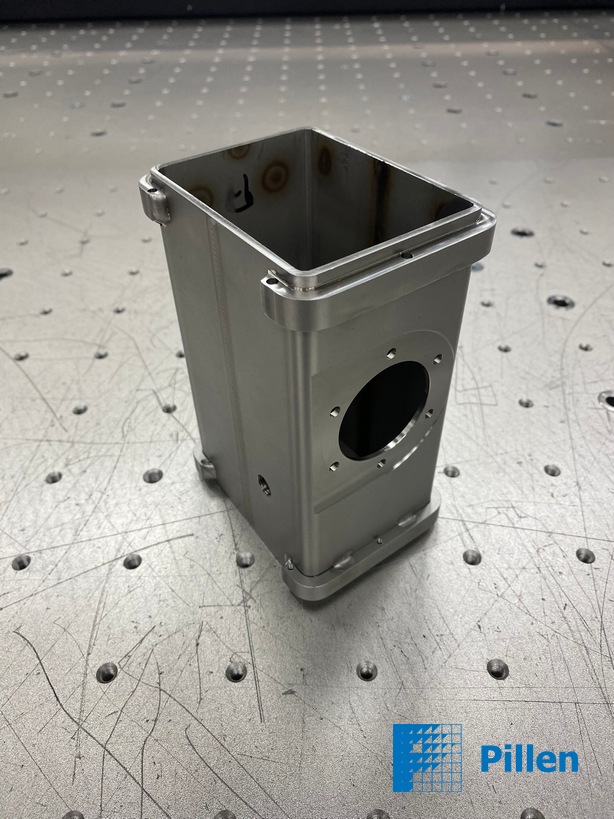

The housing shown below is a component that is used for gas and control technology. The production and manufacture of these body covers requires high precision accuracy.

More information?

Description

Series sizes and production

The body covers are produced in medium and large series. From hundreds to thousands of pieces. Our 24/7 precision mechanical machine cells are used here, equipped with pallets and/or supplemented with a robotized process.

Materials

The body covers that we make can consist of various materials such as aluminum, aluminum extrusion profile, steel or stainless steel. In the example shown below, we use stainless steel starting material that is certified by means of a 3.1 or, if desired, a 3.2 certificate and is therefore traceable.

Within the Pillen Group, Pillen Precision, among others, is authorized/certified to re-stamp materials (GO304). This guarantees the traceability of materials. If desired, we can also provide a complete PED registration.

The choice of material is determined on the basis of customer specifications and we adapt our processing options/techniques to this in order to manufacture a stable product that meets the wishes of the customer.

Production

In the example shown, the body cover is made of stainless steel, with a combination of sheet metal and machining parts carefully assembled by means of robot welding. Subsequently, the housings are custom-milled in our precision machining in a fully air-conditioned environment on high-quality machines so that they meet the precise dimensions that the customer expects of these products.

Photos & images

Features

| Materials | Aluminium, aluminum extrusion profile, steel or stainless steel |

| Trailing band | 1 muh to 2 muh |

| Surface roughness | Super smooth and XYZ smooth |

| Certifications | Overstamp G0304 |

Features

Research & engineering

In consultation with the client, a material study was also carried out into the best material choice, appropriate to the requested quality / pressure of the product.

Post-processing

The body covers are then lightly blasted for a matte and smooth look.

Measure and control Technique

At the request of the customer, we send a measurement report every 10 pieces per produced batch, with the test results of the required pressure and leak tests, in which tightness is checked.

Where can you find these body covers?

Thanks to years of experience in such products/parts, Pillen Group can now call itself a specialist in the production and manufacture of body covers in measurement and control technology.