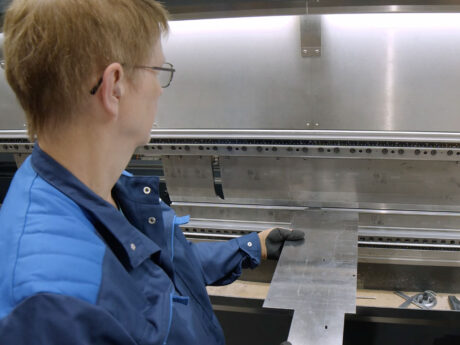

Sheet metalworking

In our CNC machining center we produce single products as well as assembled parts and sheet metal constructions. We do this for single, small and large series. This allows us to optimally respond to the processing questions of you as a customer.

Processing thin metal plates is one of our specialties. From aluminum to stainless steel mirror plate, we can handle it on our punch line and CNC laser. Regardless of the size of the series (small or large series of sheet metal processing), we strive for delivery reliability in the logistics system within Pillen.

Sheet metalworking with our own machinery

Below is a summary of the different types of sheet metal processing that we carry out in our own machine park. Click on the links to read more about the specific sheet metal processing:

Would you like to know more about our sheet metalworking?

Do you have a question about processing thin metal plates? Please feel free to contact us. You can call or email us.

It is also possible to fill in the contact form. We will then contact you as soon as possible.

Opening hours

By phone: 08.00 – 16.45 hrs

Visiting hours: 08.00 – 17.00 hrs

Expedition: 08.00 – 16.15 hrs