Metalworking

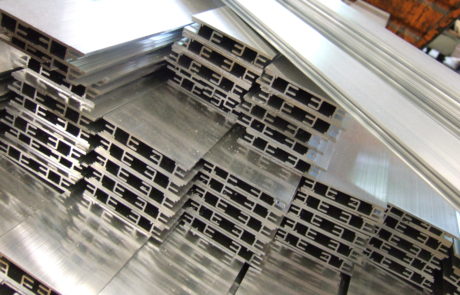

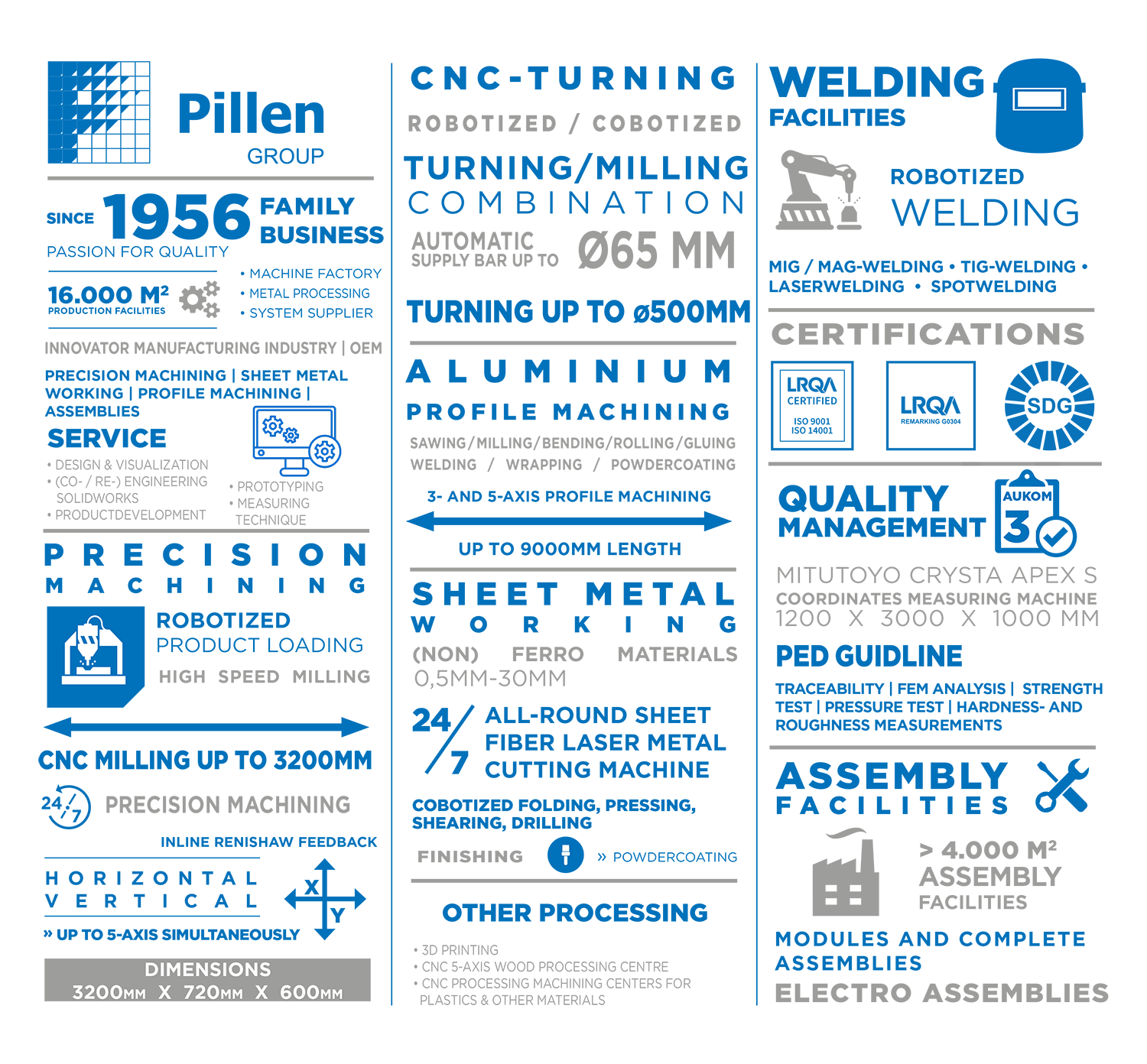

Pillen Group has been a specialist in metalworking since its foundation in 1956. Decades of expertise and experience have made us one of the leading suppliers in sheet metalworking, profile processing and precision machining.

Our team consists of highly technical specialists. They work with the most modern techniques. As a result, we can handle practically all forms of metalworking. From relatively simple to highly complex compositions.

Various metalworking

Machine park in own management

We have our own machinery that can be used to process a wide variety of materials. From single pieces to large series.

Prior to the processing that we carry out, we can convert your engineering issue into a technically workable document. That makes us one point of contact for your product.

Challenge us and let’s make your product or idea a success together!

Want to know more about our metalworking?

Do you have a question about the metal processing we perform? Please feel free to contact us. You can call or email us.

It is also possible to fill in the contact form. We will then contact you as soon as possible.

Opening hours

By phone: 08.00 – 16.45 hrs

Visiting hours: 08.00 – 17.00 hrs

Expedition: 08.00 – 16.15 hrs