Profile processing

Profile processing

Skilled in shaping versatile aluminium

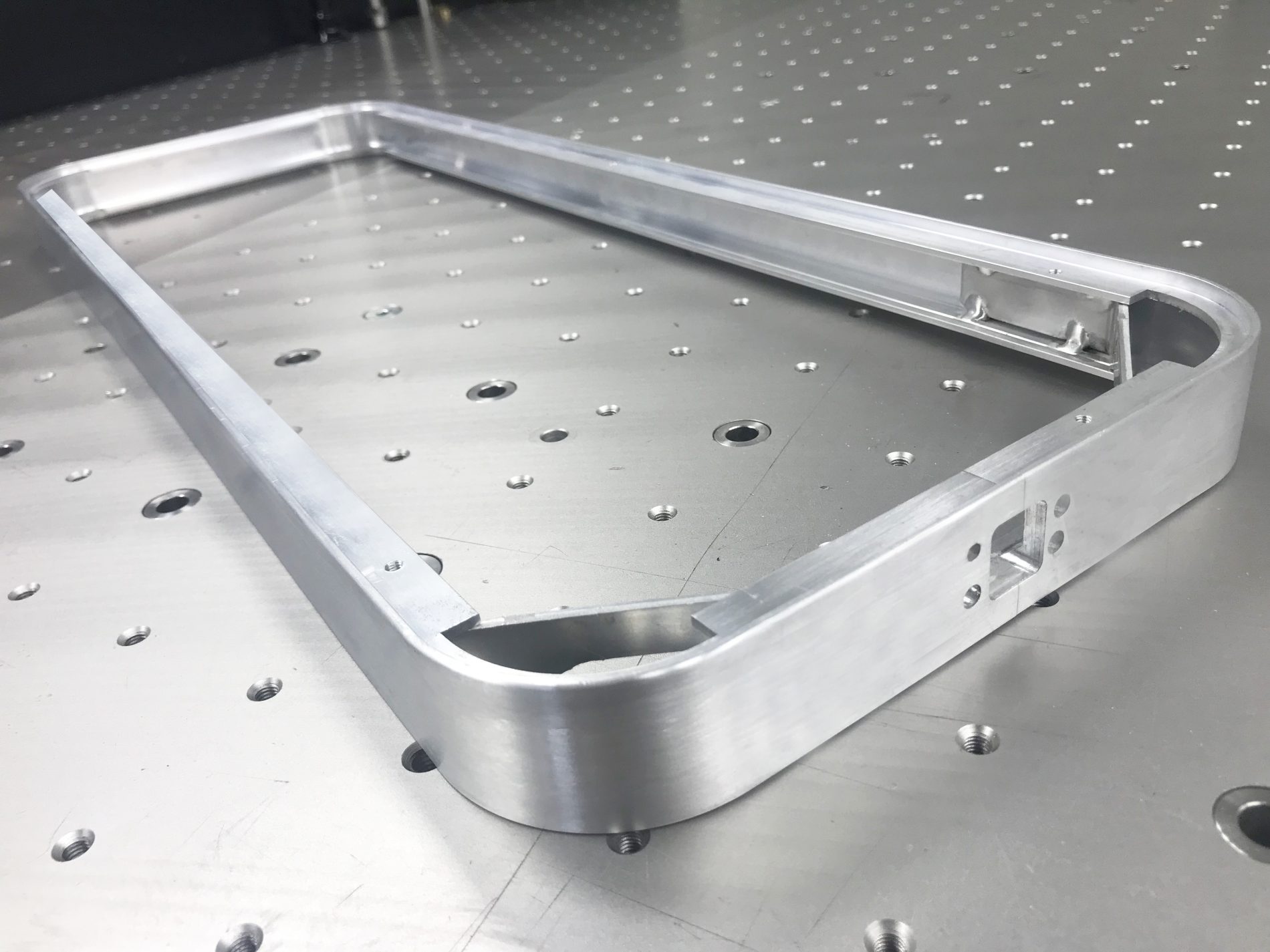

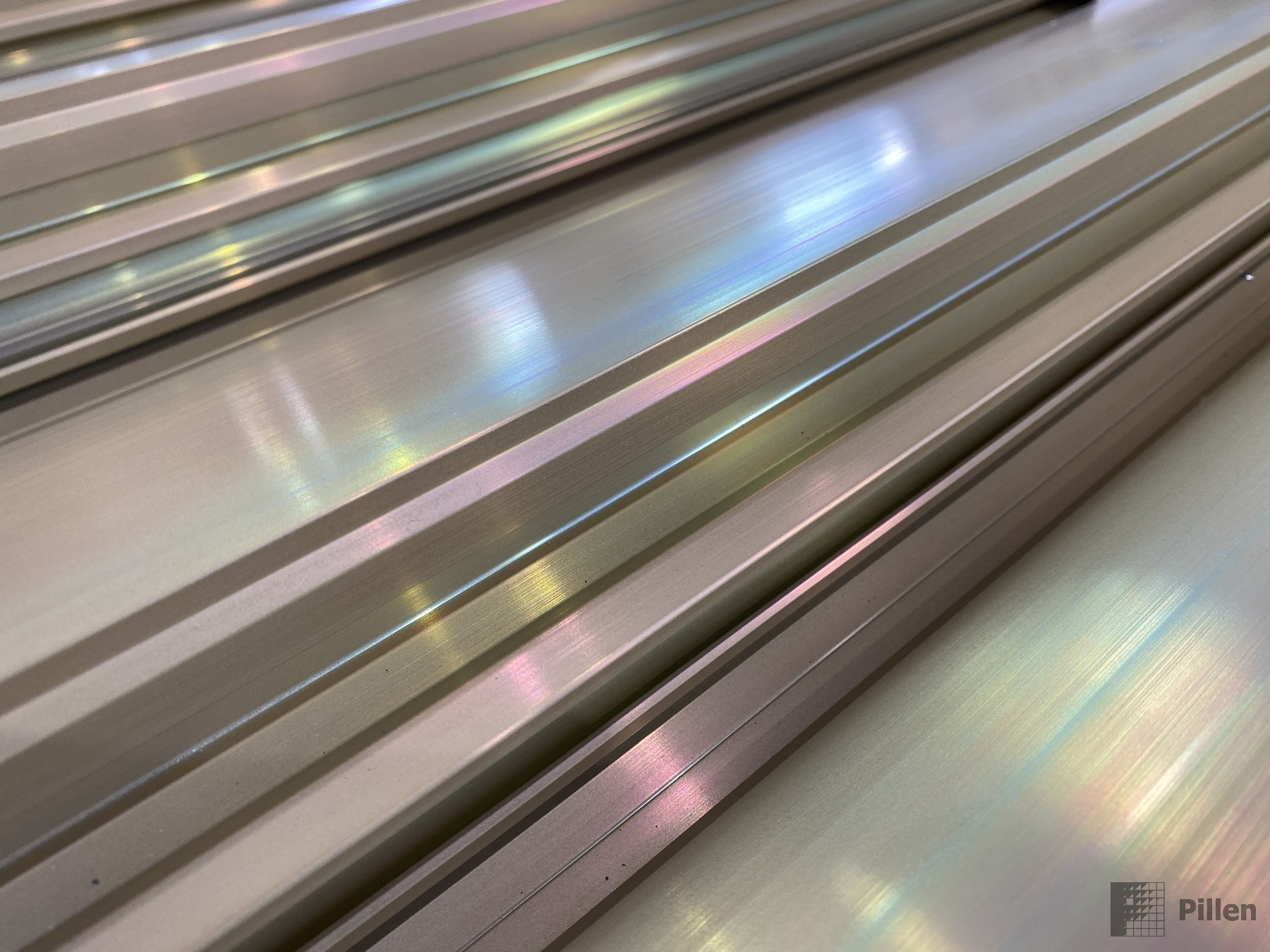

Our technical heart beats faster when machining aluminium extrusion profiles. In the supply chain, we are the perfect link for machining aluminium extrusion parts directly from the extruders. Ranging from simple sawing operations to more complex 5-axis milling profile operations suit our profile machining facilities.

Profile processing with our own machinery

You the profiles, we the processing

Storage and transhipment facilities for aluminium extrusions

We have storage and transhipment capacities where our clients can store the aluminium extrusion profiles they supply can be stored. This has the advantage that the aluminium stock can be drawn on in case of direct production demand. This saves time, transport and handling costs. The knowledge we have in the field of engineering aluminium structures, aluminium processing and the end application in terms of stability and weight we would like to share with our clients to realise the perfect aluminium machined profile, optionally combined with the complete composition of the end result.

The operations we perform on the profiles are:

- Sawing extrusion profiles

- CNC profile milling 3 & 5-axis up to extrusion lengths of 9 metres

- CNC bending/rolling

- CNC welding/jointing: gluing, welding

We process our aluminium profiles for the;

- Interior construction;

- Linear industry (logistics& distribution systems);

- Medical industry;

- Lighting industry;

Reichenbacher Vision-Flex profiling machine

The Reichenbacher Vision-flex is an advanced profile machining machine that excels in large workpieces, flexibility, precision and versatile applications. This advanced 5-axis CNC machine is specially designed for machining larger profile cross-sections, making it ideal for the production of aluminium profiles. The Reichenbacher Vision-flex is distinguished by:

✔ Large machining range, ideal for long and wide profiles.

✔ CNC precision with 3-, 4- or 5-axis machining, suitable for complex shapes.

✔ Versatility in material processing, from wood to aluminium and composites.

✔ Automatic tool changer and smart sensor technology, saving time.

✔ Sturdy, low-vibration construction, for a smooth finish.

✔ Expandable modules and software integration, suitable for custom and series work.

Our competences

Machining profile lengths up to 9000 mm

Our 3- and 5-axis machining centres are capable of machining aluminium profiles in lengths of up to 9000 mm. The profiles can be milled, drilled and/or tapped in one go.

Creating round / organic shapes in aluminium (blank and anodised) profiles

If curves / organic shapes need to be created on an aluminium extrusion profile, we will do it. In some cases, we will first make a test to determine whether the desired bend can be achieved in the profile. By bending/rolling the profile, the relevant curve is created as an operation. For this, we use a washing roller method that requires little or no finishing.

Seamless joining of aluminium profiles

To make an angle connection in an aluminium extrusion profile, we can use a welding method or glue joint. Finally, we can also organise the desired post-processing operations (such as powder coating) for the profiles.

The connection to our sheet-metal working

The aluminium profile processing is internally connected to our sheet-metal processing. As a result, all sheet and profile components can be produced by us. This saves time and organisation and thus reduces cost prices in the chain.

Opening hours

By phone: 08.00 – 16.45 hrs

Visiting hours: 08.00 – 17.00 hrs

Expedition: 08.00 – 16.15 hrs