Sheet metalworking

Sheet metalworking

Powerful in processing delicate sheet materials

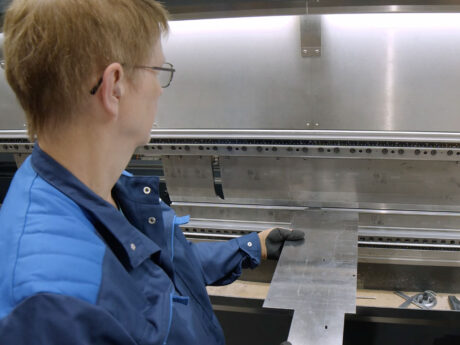

We like challenges and mostly work with thin reflective (aluminium) sheet materials in our sheet metal processing. One of the fastest fibre CNC-controlled laser cutting machines makes it possible, together with our technical team, to realise a low cost price per part/product combined with very high quality and precise tolerances for our national and international clients as a sheet metal working machine.

Sheet-metal working with our own machinery

Medium-sized series and assembly facilities

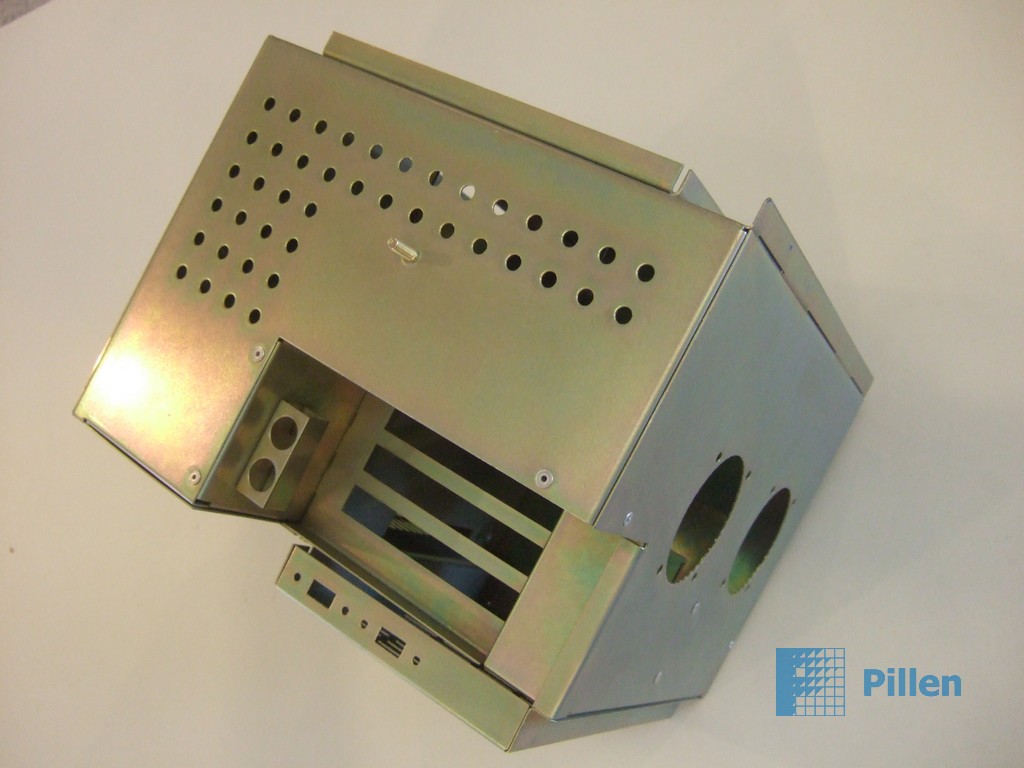

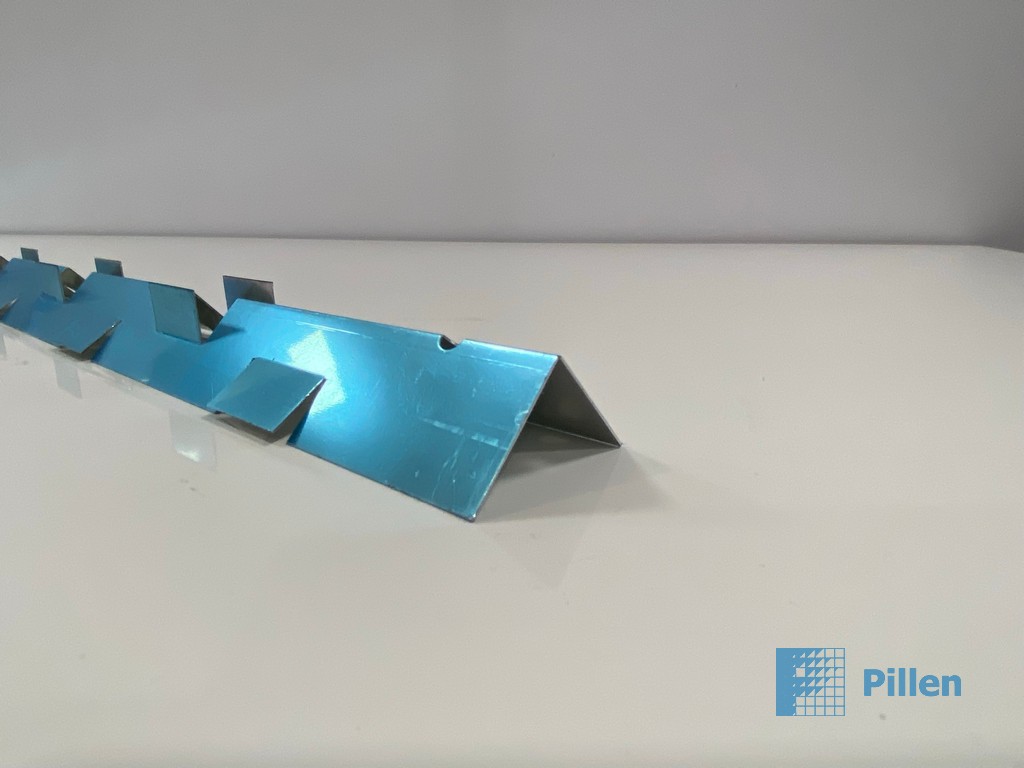

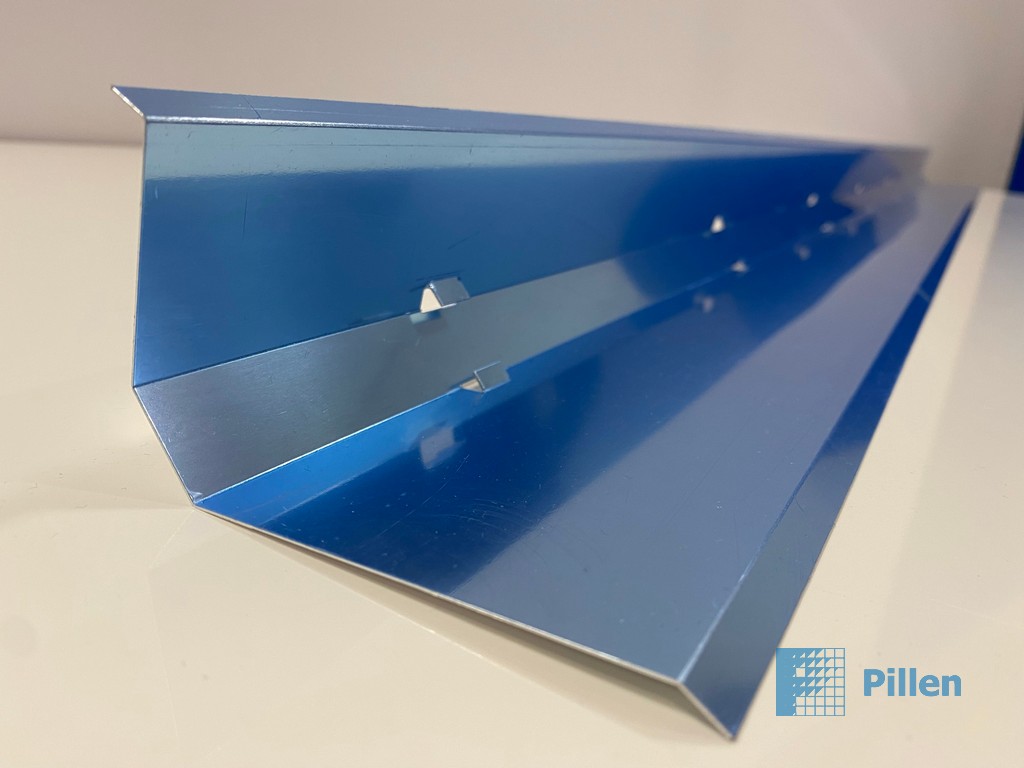

In our sheet metal working, too, the focus is on producing components, modules and/or assemblies in medium-sized series that are also reciprocal. Especially in machining to special lightweight (reflective and absorbent) thin sheet materials, we are a specialist. We offer our clients the opportunity to combine this thin sheet machining with our special (aluminium) profile machining. A unique combination for the benefit of the production challenge! Target markets where we supply thin sheet machining and modules are:

- Renewable energy;

- Machine and equipment construction

- Medical industry;

- Retail – interior construction;

- Lighting industry

For these clients, we realise e.g. lighting fixtures, parts for interior elements, covering materials such as (electrical) casings, housings and devices for (medical) analysis equipment, etc.

Our competences

All-round fibre laser cutting machine for sheet materials

Our fully automatic fibre laser cutting machine realises the required sheet metal parts at very high speed and precision. Sheet materials with maximum dimensions of 3000×1500 mm can be processed on the fibre laser cutting machine.

Powerful in processing delicate sheet materials

Our production facilities are primarily designed for thin sheet metal. The 24/7 fibre laser cutting machine stands for the production of rashes and, combined with a large line of CNC-controlled press brakes, this production line enables us to process medium to large series of vulnerable sheet materials quickly and efficiently at top level. With our decades of experience in the lighting industry and interior construction and always thinking along with our partners in finished products, we are able to continue to guarantee the required quality.

Welding facilities and methods

To join sheet metal or plate material from different metal types, we use various welding joints and have the necessary welding machines and robotic set-ups. We are also able to develop Customer-specific Welding Method Qualifications (LMKs).

We carry out the following welding methods:

- MIG/MAG welding

- TIG welding

- Laser welding

- Spot welding

- Finishing

To strengthen and protect the processed sheet metal and keep it scratch-free, for example, post-processing (surface treatment) can be used, such as powder coating or galvanisation.

Opening hours

By phone: 08.00 – 16.45 hrs

Visiting hours: 08.00 – 17.00 hrs

Expedition: 08.00 – 16.15 hrs